Custom made injection moulding is commonly a specialised process that enables companies to deliver plastic parts and components designed to meet up with specific necessities. In contrast to standard injection moulding, which usually produces off-the-shelf items, custom injection moulding is centered on flexibility, precision, and innovation. It’s ideal for corporations that demand special styles, components, or performance inside of their solutions.

What exactly is Personalized Injection Moulding?

Custom made injection moulding consists of building a bespoke mould and deciding on acceptable elements to generate pieces which happen to be customized to your customer’s specs. This method begins with an in depth style and design stage, normally employing Pc-Aided Style (CAD) computer software, accompanied by the fabrication of a custom Resource or die. When the mould is produced, molten plastic is injected associated with it under closing dates, forming a distinctive ingredient that matches the design specifically.

Advantages of Personalized Moulding

The main advantage of customized injection moulding would be the capability to provide remarkably specialised areas. Regardless of whether it’s a complicated shape, a good tolerance, or even a precise material prerequisite, this technique can provide outcomes that off-the-shelf elements simply cannot match. It also offers large repeatability, making sure Each individual aspect is constant in good quality and gratification.

Personalized moulding can also be scalable. When the First mould is designed, technological innovation-not simply here to crank out countless numbers or perhaps an incredible range of identical pieces effectively. This causes it to be a cost-efficient Option for prolonged-expression generation, get the job finished upfront tooling price ranges are larger.

Applications in Sector

Personalized injection moulding is employed throughout numerous industries, which include automotive, clinical, gizmos, and industrial tools. As an example, a clinical machine business might need a plastic casing with constructed-in antimicrobial Homes, though an automotive maker could need higher-strength components resistant versus heat and chemicals.

Material Options

Yet another good thing about custom made injection moulding can be the number of resources out there. From rigid ABS and impact-resistant Polycarbonate to versatile TPU and chemical-resistant Nylon, purchasers can pick out the plastic that most carefully matches their application.

Partnering with Gurus

Working Together with the skilled injection moulding organization like Australian Consolidated Plastics signifies that every stage—from design and style and prototyping to tooling and manufacturing—is dealt with with skills. Their functionality to offer finish-to-finish support allows purchasers lessen advancement a while to carry solutions to publicize faster.

Summary

Customized injection moulding is known as a highly effective production Remedy that gives precision, flexibility, and effectiveness. No matter if for prototyping or massive-scale generation, it enables businesses to turn ground breaking Concepts into high-quality plastic products and solutions tailor-made on their exact requirements.

Alana "Honey Boo Boo" Thompson Then & Now!

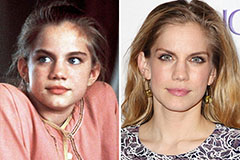

Alana "Honey Boo Boo" Thompson Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!